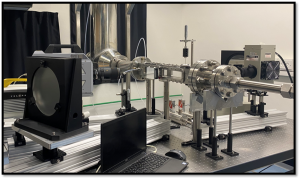

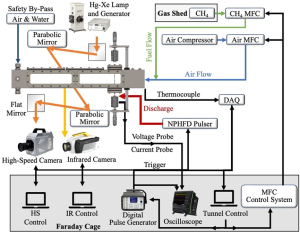

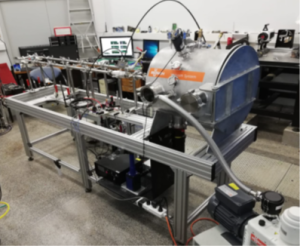

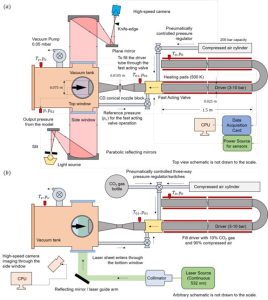

A Mach 6 Hypersonic Ludwieg Tunnel (HLT) test facility was commissioned and operating since October 2021 under the Technion Wind-tunnel Complex (TWTC). The facility is 3 m long and 22 mm in diameter (inner). The tube is arranged in a ‘U’-tube configuration to save some floor space. The tube is wrapped by heater pads which can maintain a surface temperature of up to 500 K. At one end of the tube, a commercial fast-acting valve. The tube is pressurized to the desired fill pressure ranging between 3 to 10 bar. A convergent-divergent(C-D) nozzle whose interior is mirror-polished to have a smooth wall surface with a roughness radius of about 0.1 μm. The nozzle expands freely into a closed chamber of volume 0.1 cubic meter and 0.5 m long, which is kept to a vacuum level of 0.05 mbar using a rotary vacuum pump.

A wide range of Reynolds numbers (4.75 million to 18 million) is achieved with flow test time of ~12.5 ms and the effective model diameter that can be used is found to be 40 mm.

A typical layout of the experimental facility along with the optical diagnostics (a. schlieren, and b. laser Rayleigh scattering) and photographic picture of the facility is shown in the figure below.

Click here for more details about the facility

Karthick, S.K., Nanda, S.R. & Cohen, J. Unsteadiness in hypersonic leading-edge separation. ExpFluids 64, 13 (2023). (https://doi.org/10.1007/s00348-022-03559-7)